I have very little experience with hot process soap, but I really wanted to give it a try. I think the rustic look of some hot process soaps is quite pretty. I had an idea for a soap, and I thought it might look better if it were hot process rather than cold process, so I decided to give it go.

First, my recipe:

- 40% olive oil

- 25% coconut oil

- 25% palm oil

- 5% castor oil.

This is my “test” recipe, which also has the advantage of being a good basic recipe.

I made up the lye mixture with full water and set it aside. Then I added the oils to the crock pot.

I grew really impatient waiting for them to melt. They probably took about 15 minutes to melt on high heat.

Then I added my lye. I thought I was being really smart lining my crock pot. I forgot about the stick blender blades. Still, very little of the soap leaked into the crock pot itself. Next time, I just won’t bother. After all, with hot process, the soap is fully saponified, so the lye is not going to be a problem. I didn’t add my fragrance to the soap while it was in the crock pot, so there was no danger of fragrance leeching into my food later.

I blended to light trace. It took maybe a few seconds. You can barely see the soap trails on the top.

Next, I stirred it a bit before letting it sit to cook. At this point, I turned the crock pot to low. Notice you can see a bit of the separation you are supposed to look for.

I let it cook for a bit, perhaps 10 minutes, and when I came to check on it, it was thickening up quite a bit. At this state, it was maybe the texture of thick pudding or mashed potatoes.

I actually checked on it quite often. I was nervous about leaving it alone. I should have paid better attention to timing here, but since I was checking it so frequently, I really looked more for “signs” instead of watching the clock. I started to notice it was gelling near the edges, like it was supposed to do.

So, I stirred it up, and the gelled soap combined with the soap in the middle looked more like applesauce.

I cooked it a bit longer, looking for signs it was turning fluffy. Sure enough, I started to see the fluffy stage.

Then when it started to pull away from the edges, I did a zap test. It wasn’t quite done yet, so I let it cook a bit longer and did a second zap test. This time, no zap.

Then when it started to pull away from the edges, I did a zap test. It wasn’t quite done yet, so I let it cook a bit longer and did a second zap test. This time, no zap.

I scooped the soap out of the crock pot and put it into a bowl. This is where I think I could use some advice from more experienced hot process soapmakers. I wanted to let the soap cool a bit so it didn’t burn off the delicate orange essential oil I wanted to use (though, to be fair, it was 10x orange oil).

I scooped the soap out of the crock pot and put it into a bowl. This is where I think I could use some advice from more experienced hot process soapmakers. I wanted to let the soap cool a bit so it didn’t burn off the delicate orange essential oil I wanted to use (though, to be fair, it was 10x orange oil).

I think I let it cool too much. I read at TeachSoap that it’s a good idea to add a bit of sunflower oil (or, I suppose another carrier oil) to help cool the soap and make it more pliable as I mix the fragrance. Do any of you do this? Does it work? Because I tried to wait until my soap was right around the flashpoint for orange essential oil, and I think it was too cool. I had some trouble getting it into the mold, which I understand is just part of the nature of hot process soap, but I am wondering if the oil would have helped. Any advice is appreciated.

I added the orange essential oil, and it was very hard to mix. My soap is going to have a really cool mottled look because I couldn’t get the oil to mix as thoroughly as I had planned.

After I mixed the oil, I plopped it in the mold, and tried to stop fiddling with it, but I wasn’t successful.

After I mixed the oil, I plopped it in the mold, and tried to stop fiddling with it, but I wasn’t successful.

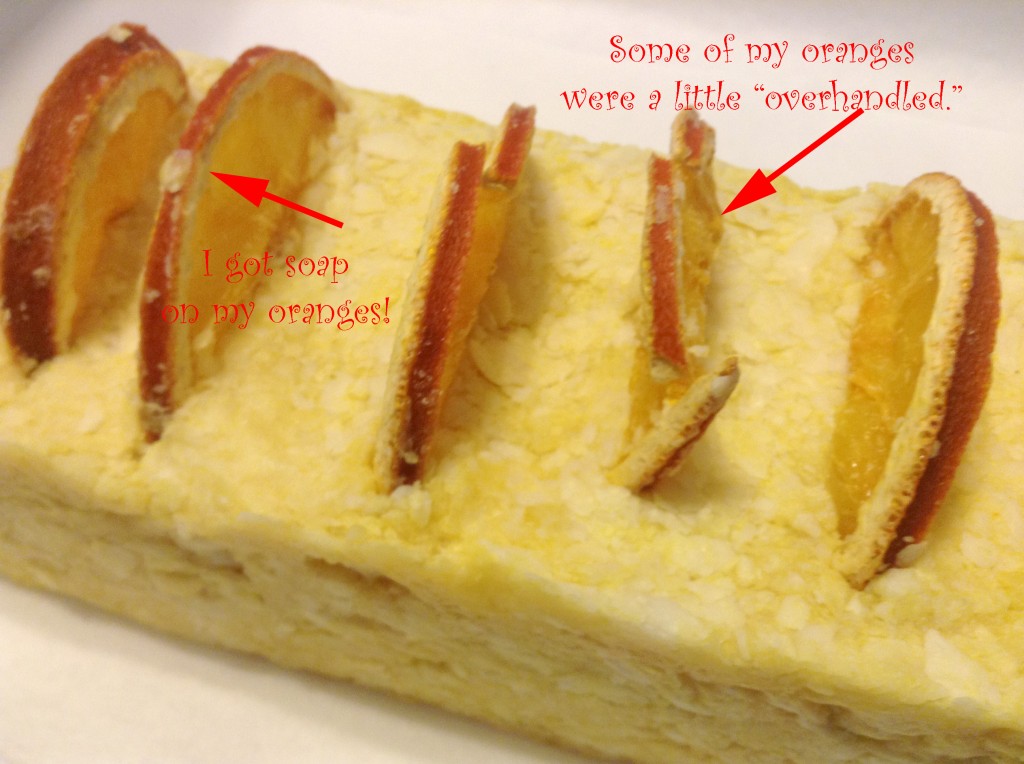

As you can see, I put some dried orange slices in the tops of the bars. Pretty!

As you can see, I put some dried orange slices in the tops of the bars. Pretty!

Here is another view of the soap in the mold.

Eventually, I quit fussing with it and let it set up. I unmolded it and decided to let it harden a bit more before I cut it. You can tell I fussed with it too much because I got soap all over my oranges. Boo! I decided to clean them off after I cut the soap. The pictures are a little darker because the light wasn’t as good by the evening when I took them.

Here is another view of the soap loaf with the manhandled (womanhandled?) oranges in clear view.

I am really digging the mottled look. It made me wonder if this is how Gossage’s soap got its famous “mottled” look. I know they experimented with adding colorants, but I couldn’t find out if their manufacturing process was hot process or not. I can’t find a picture of Gossage’s soap (just the packaging), so I’m not really sure what it looked like.

After the soap was cooled, I cut it as I normally do with my soap log cutter. Here are the results.

I am thinking of calling it Sunrise. I am not sure if I will sell it or if I will just give these away. However, I am giving one bar away here. Just follow the instructions to enter. Good luck!

I LOVE the way this came out Dana…it perfectly suits and orange themed soap! And considering how cool it was by the time you molded it, it came out very smooth. I actually hold back some of my liquid to add after the cook, and I also add a little bit of oil to the soap after the cook too. I only let my soap cool about 10 mins before adding the liquid, oil and fragrance, in that order.

Cee recently posted..Coconut Cream Soap

Thank you! That is really helpful. I will try that next time.

Very good choice for a test recipe. Keep it up!

Thank you!

hi, Dana!

HPer here. I love that you went for it with an orange EO…sounds yummy!

Personally, I find that I have to stir, stir, stir my batch post-cook to keep bits of it from solidifying. If I need to bring the temperature down, that's usually how I do it, making sure not to try to hit some crazy cool temperature (at some point, you have to get it to the mold and unless I've gotten overly ambitious, my soap always looks like it's still in full gel by the time it's molded). Also, having the batch touching anything that is a vastly different temperature than the soap mass seems to exacerbate the problem with the solid bits.

I don't add any oil post-cook just because I feel like I'm tempting fate with having that extra oil go rancid, but totally intrigued to see how Cee's are coming out now that she mentions she does it.

Only other things I can think of are potentially increasing the water you're using in your lye solution – you can easily use 25% lye solution to help keep your batch fluid at the end of the cook – and using some sodium lactate, which will also keep the batch nice and loose.

Hope you get some more crazy HP ideas!

I stirred it a lot, which I think is the only reason it didn't stick in the pot even worse. Thanks for the advice!

Oh yes, definitely the sodium lactate too…forgot about that key ingredient that Jen mentioned above! Also, I use the full liquid amount as she mentions too. I've never had a problem with randicity in adding the oils after the cook, but I only use about 1 tbsp of extra oil per 2 pounds of base oils.

Cee recently posted..Coconut Cream Soap

How much sodium lactate do you typically use? Thanks for all your advice!

I use 3% ppo for hot processed soap, and I add it to the lye solution.