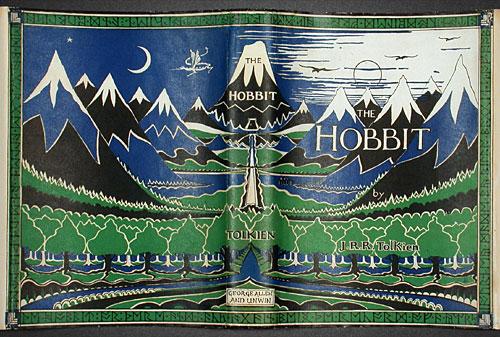

If you use titanium dioxide and gel your soaps, you might occasionally run into an issue called titanium dioxide crackle, also known as glycerine rivers. Here is what it looks like:

If you look closely at the swirls, you can see spots that look more clear and there is a sort of crackle effect in the soap.

You can see it here in this Candy Cane Soap as well, especially in the soap on the left.

Anne-Marie Faiola says in Soap Crafting: Step-by-Step Techniques for Making 31 Unique Cold-Process Soaps that these clear streaks are “caused by a combination of heat and color additives” (235). I have noticed these glycerine rivers even in soaps that I have not colored. They are a little easier to see in person, but if you look very closely at this Vermont Maple Syrup Soap, you can barely see them:

Usually the culprit is titanium dioxide. I never realized this before, but all oxides can actually accelerate trace. In this video Amy Warden of Great Cakes Soapworks describes the effect oxides can have on accelerating trace:

Amy was using some fragrances that were spicy in addition to oxide colorants. Spicy fragrances can cause the soap to heat up quite a bit, as in this Pumpkin Cheesecake Soap. My intention was to do a drop swirl, but I did a sort of combination of a drop—more of a “plop”—and a spoon swirl. Here is the resulting soap:

You can see I do have some of the glycerine rivers, especially in the part of the white that mingled with the bottom color, which was the only scented portion of the soap. My theory is that part of the soap was much hotter than the soap on the top.

The only problem with glycerine rivers is a cosmetic one. The soap is perfectly usable. In fact, sometimes it looks really interesting and adds a sort of antique effect to the soap.

I haven’t always been successful at preventing it, but these two soaps were both gelled, and I was able to prevent titanium dioxide crackle by monitoring the temperature of the soap and removing towels when it was getting too hot.

I wanted to gel both of these soaps so that the blue would really pop. Colors are often more vibrant when the soap is gelled.

In the summer, I don’t seem to need to cover my soaps much to ensure gel. I just put the soap mold into a large box, and that seems to be insulation enough. As the weather becomes cooler, I need to work a little harder to ensure gel, which means putting at least one towel over my soap mold inside its box. I usually fold a bath towel in half and drape it over the box containing the mold. I use the box so that my tops are not ruined, by the way.

I check the soap’s temperature every once in a while, and if it looks like it’s too hot, I remove the towel or at least unfold it. I didn’t monitor either of the two soaps at the top of this post (Winter Sleigh Ride and Candy Cane), hence the crackle. I imagine that the soap was a little too warm in its bed because the fragrances I used are well-behaved.

There have been plenty of times I thought for sure my soap would have titanium dioxide crackle, and it didn’t. I honestly can’t seem to predict very well when it will happen, but generally speaking, keeping a really close eye on the temperature seems to help. Unfortunately, you don’t always know when the soap is getting too hot. It’s not always easy to tell. In my opinion, partial gel looks worse than titanium dioxide crackle, so I tend to err on the side of letting the soap fully gel rather than expose it to the cooler outside air and risk partial gel.

Once piece of advice Anne-Marie has in her book is to lower soaping temperatures to avoid glycerine rivers; however, in the case of both of the above soaps, I did lower temperatures and wound up with crackle anyway. In the case of the Winter Sleigh Ride and Candy Cane soaps, I like the resulting look. I think it works especially well in Winter Sleigh Ride.

The best way I have found to avoid glycerine rivers altogether is not to gel my soap. I have to put mine in the freezer for at least a couple of hours before moving it to the refrigerator, where I leave it for a day or two (sometimes even longer). When I take out the soap, I have to leave it in the mold at least another day, sometimes more, and sometimes it isn’t ready to cut for at least week after it’s been made. I like being able to cut the soap the next day, especially because I only have two log molds. However, if I really want to avoid the glycerine rivers, I will prevent gel.

Have you had problems with glycerine rivers? How did you solve them?